Production & Quality

Design Development

LIGMAN are 100% dedicated and focused on the quality and design of our luminaires. We select only the highest grade of components and design their integration within fixtures using our many years of experience and technical know-how. We are continuously improving and evolving new ranges, with new inspirations, unique designs, a wider range of finishes and the latest innovative technologies.

Design & Prototyping

LIGMAN products are designed using only the latest CAD/CAM software available in the marketplace and using a variety of high-tech tools to create new prototypes for testing and final production tooling.

The product design engineers, optical design engineers, testing engineers and production engineers work together to develop all new luminaires with the highest quality, highest efficiency and optimal value for our customers.

Materials

LIGMAN uses high corrosion resistance, extremely low copper content LM6 aluminum alloy for our high-pressure diecast luminaire body castings. All fixtures are finished using our superior powder coating process, with double powder coating also offered as an option if desired for extreme environments.

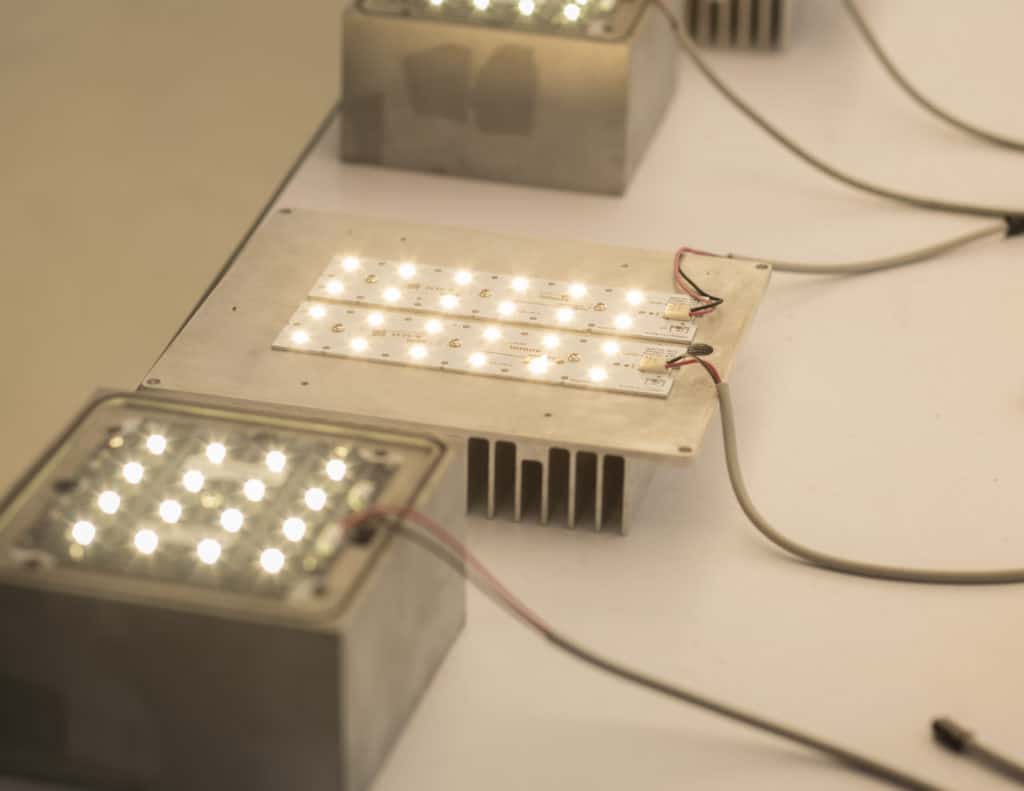

In addition, for key internal components such as LED heatsinks we use ADC12 aluminium alloy. This material is used in the automotive industry for mechanical strength and excellent thermal dissipation, ideally suitable for low and high ambient temperature applications. LIGMAN also verifies heatsink designs through thermal imaging techniques before commencing commercial production. This enables us to ensure less than 10% lumen depreciation at 50,000 hours for all our products.

Testing Laboratories

We built the laboratory center to ensure our products exceed the design and quality requirements set out by international standards. All measuring tools are consistently serviced and updated to the latest technology, with additional measuring implements introduced to cover more metrics.

Our state of the art laboratory has been inspected and tested in accordance with international testing standards.

Each of our products are carefully tested with the following luminaire standard tests in accordance with the international standards requirements:

– Electrical Testing

– Mechanical Testing

– Resistance to Dust, Solid Objects and Moisture

– Endurance Tests and Thermal Tests

– Salt Spray Testing

– Photometric Testing

– Performance of LED Module

IEC 60598 Ingress Protection of Luminaires

IEC 62262 Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IK code)

IEC 60529 Degrees of protection provided by enclosures (IP Code)

ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus

IESNA LM-79-08 Electrical and Photometric Measurement of Solid-State Lighting Products

CIE publication 121-1996 The Photometry & Goniophotometry of Luminaires

IEC 62717 LED modules for general lighting – Performance requirements

IES LM 79-08 Electrical & Photometric Measurement of Solid-state Lighting Product (Accredited ISO 17025 by TISI)

EN 13032-1:2004 Light and lighting. Measurement and presentation of photometric data of lamps and luminaires – Measurement and file format

IES TM-30-15 IES Method for Evaluating Light Source Color Rendition

Electrical Testing

– Provision for earthing (IEC 60598)

– Insulation resistance and electric strength, touch current (IEC 60598)

– Protection against electric shock (IEC 60598)

EMC/EMI Testing

– Conducted Emission measurement and Radiated Electromagnetic disturbance from 9 kHz to 30 MHz

– EMC/EMI conformance with the requirements of CISPR publication 15 (EN 55015)

Mechanical Testing

– Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IEC 62262)

– Impact energy resistant (IEC 60598)

– Torque testing (IEC 60598)

Resistance to Dust, Solid Objects and Moisture

– We can test IPX2 to IPX6 for water and IP2X to IP6X for solids (IEC 60529)

– For IPX8, we can test at depth of 50 meters by compression testing machine

– Humidity chamber can test maximum humidity at 98% and temperatures from -40 to +150 degrees Celsius

Endurance Test and Thermal Test

– Walk-in chamber and enclosure for endurance and thermal testing

– Endurance and thermal testing in according with IEC 60598

– Maximum temperature of 60 degrees Celsius

Salt Spray Testing

– Salt spray test environment (ASTM B117)

– Can accommodate samples up to 1500 mm long

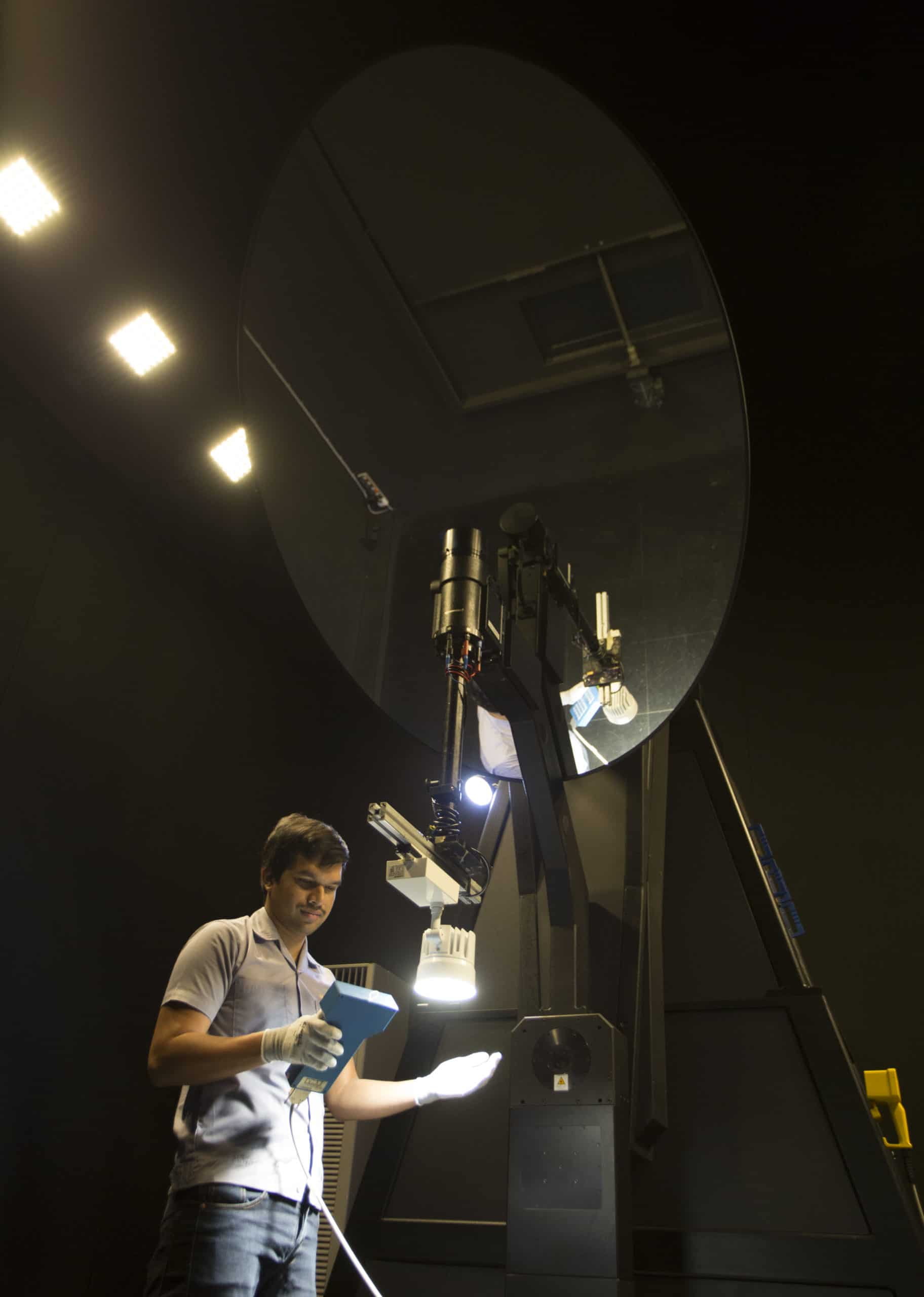

Photometric Testing

At LIGMAN’s photometric laboratory we have an integrated sphere and

the latest full-scale goniophotometer made in Germany by LMT to strengthen LIGMAN’s photometric test and measurement capacities. This demonstrates our commitment to continual development with our in-house capacities for providing global markets with products of the highest proven quality.

Our photometric laboratory can generate photometric files such as IES and Eulumdat LDT. Measurements are executed in accordance with a number

of international guidelines, most notably IES LM 79-08, CIE publication 121-1996, EN 13032-1:2004 and IES TM-30-15.

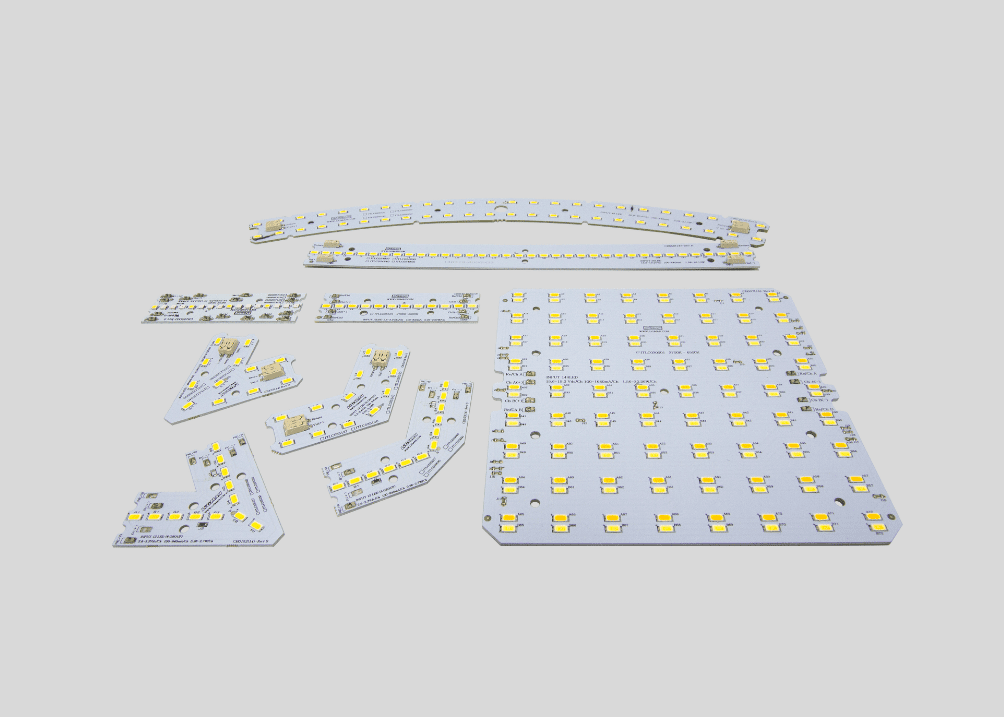

Performance of LED Module

– Lumen maintenance

– Endurance tests

– According to IEC 62717 (LED Modules for General Lighting)

– Temperature cycling test

– Supply switching test